INTRODUCTION AND PROCESS

Some products can generate potentially explosive environments (dust, oxygen, heat, reagents, etc.).

Inertisation consists in converting an inert gas in the explosive environment in order to reduce the risk of explosion or fire.

The sensitive product can thus be used safely. CO2/N2 is used as an Inert gas to maintain a non-explosive or non-flammable atmosphere.

CO2/N2 amortization is a residue-free process that can be used in remote areas. The CO2 creates an atmosphere impoverishing the oxygen which makes combustion impossible; the carbon dioxide “suffocates” the combustion and also its temperature of 78,5 °C, the CO2 is a cooling agent.

An Automatic fire suppression system which detects temperature rise that can cause fire and purges CO2/N2 to prevent the equipment and surrounding from danger. Design as suitable for any equipment to prevent from fire with safety measures and economic aspects.

SALIENT FEATURES

Customised design and Suitable for any industrial equipment.

Follows NFPA standards.

Guaranty safety.

Control panel.

No damage to equipment, electrically nonconductive

Nitrogen reduces oxygen level that catches fire.

ADVANTAGES

Easy to install and maintain.

Low cost system.

Completely safe.

Can refill Co2/N2 after purging.

APPLICATIONS

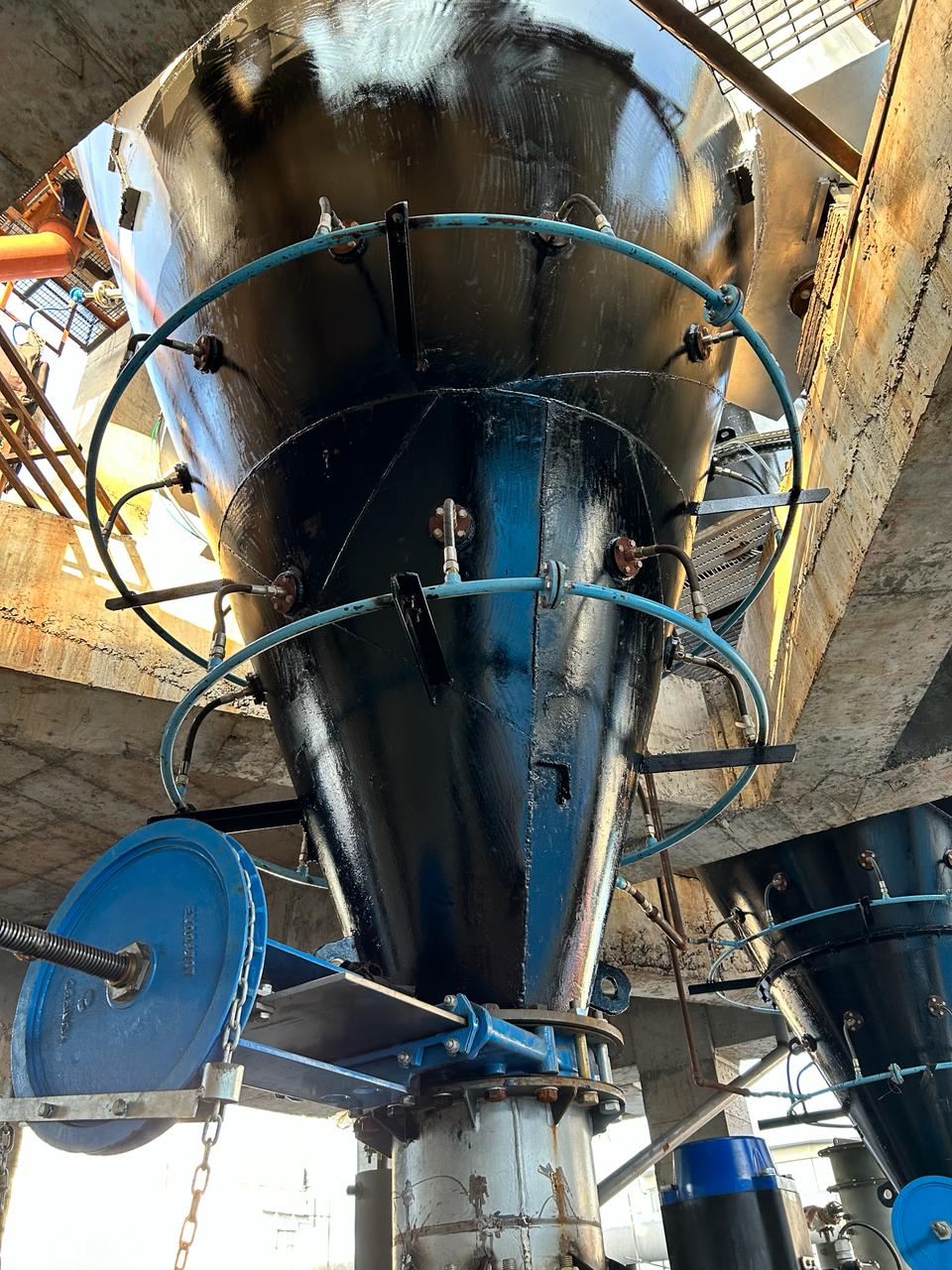

Cement Industry.

Paper Industry.

Steel Industry.

Oil & Gas Industry.

Power Plants.